Heat Exchangers

Heat exchangers are essential components in various industries, facilitating efficient heat transfer between two or more fluids. These devices are important in applications ranging from industrial cooling systems to sanitary equipment in food processing. OEM Sales Inc. stands out as a premier provider of high-quality heat exchanger solutions, offering a diverse range of products to meet your specific needs.

OEM Sales offers a complete line of Brazed Plate, Gasketed Plate, Micro-Channel Coil, Semi-Welded Plate, Fully Welded Plate, Shell & Tube, Corrugated Shell & Tube, and Shell & Plate Heat Exchangers. Our manufacturers can provide products fabricated from Aluminum, Copper, Stainless Steel, Titanium, Hastelloy C, SMO, Duplex, and others to meet a full range of OEM / Process and Industrial Applications.

PLATE

SHELL & TUBE

CORRUGATED SHELL & TUBE

MICRO-CHANNEL COIL

FAN COOLED

SHELL & PLATE

Heat Exchangers Offered by OEM Sales Inc.

At OEM Sales Inc., we pride ourselves on our extensive selection of heat exchangers, each designed to deliver optimal performance in different environments.

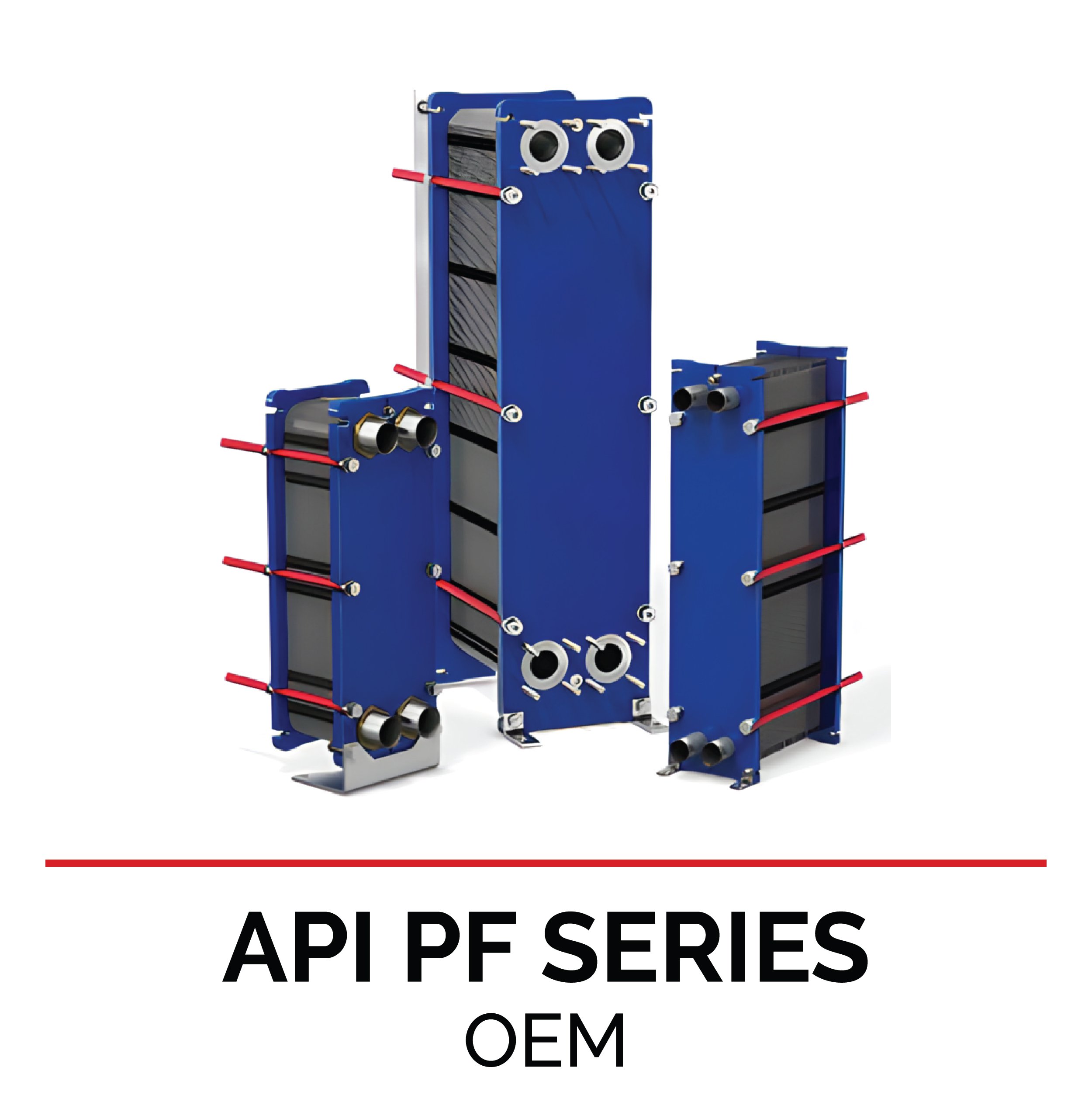

Plate Heat Exchangers

Our Plate heat exchangers are known for their high efficiency and compact design, making them an ideal choice for a variety of applications. These exchangers consist of multiple thin, corrugated plates stacked together, creating channels for fluid flow. The fluids transfer heat through the plates, allowing for efficient heat exchange.

Plate heat exchangers are widely used in HVAC systems, refrigeration, and process industries such as food and beverage, chemical processing, industrial cooling, and pharmaceuticals. The high thermal efficiency is due to the large surface area of the plates, and their compact size requires less space compared to other types of heat exchangers. Additionally, they are easy to expand or modify by adding or removing plates. OEM Sales Inc. offers a range of plate heat exchangers, each engineered for specific applications to ensure maximum performance and reliability.

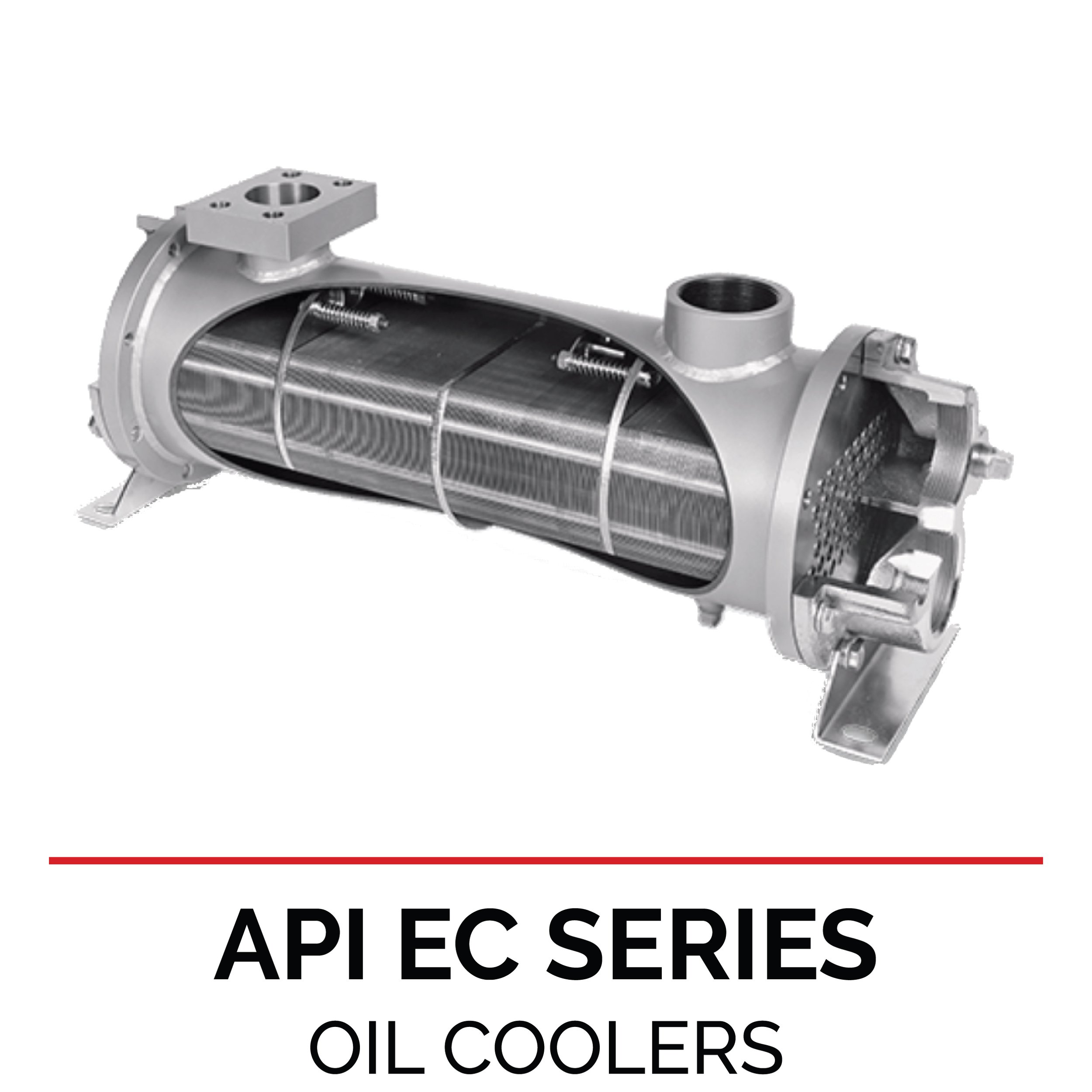

Brazed Plate Heat Exchangers

Our Brazed plate heat exchangers are a durable and efficient option, particularly suited for high-pressure and high-temperature environments. Featuring stainless steel plates brazed together using copper or nickel, these exchangers eliminate the need for gaskets, providing a leak-proof seal.

Commonly used in refrigeration, oil coolers, hydronics, fluid-to-fluid, gas-to-fluid, and industrial heating/cooling applications, brazed plate heat exchangers boast high resistance to pressure and temperature variations. Their compact and lightweight design makes them easy to install and maintain, and they offer excellent thermal performance due to the brazed construction. Our brazed plate heat exchangers are available in various sizes and configurations to meet the unique requirements of different applications.

Plate & Frame Heat Exchangers

Our Plate & frame heat exchangers offer flexibility and ease of maintenance, making them a popular choice for many industries, i.e industrial process heating and cooling, pharmaceutical, chemical, food and beverage, and renewable energy. These exchangers consist of a series of plates held together by a frame, with gaskets between the plates directing the flow of fluids to allow efficient heat transfer. Geometries include

The removable plates make them easy to clean and maintain, while their flexible design allows for easy expansion or modification. Plate & frame heat exchangers also provide high thermal efficiency and are effective in handling large flow rates. OEM Sales Inc. provides a variety of these exchangers, customized to suit specific industry needs and operational conditions.

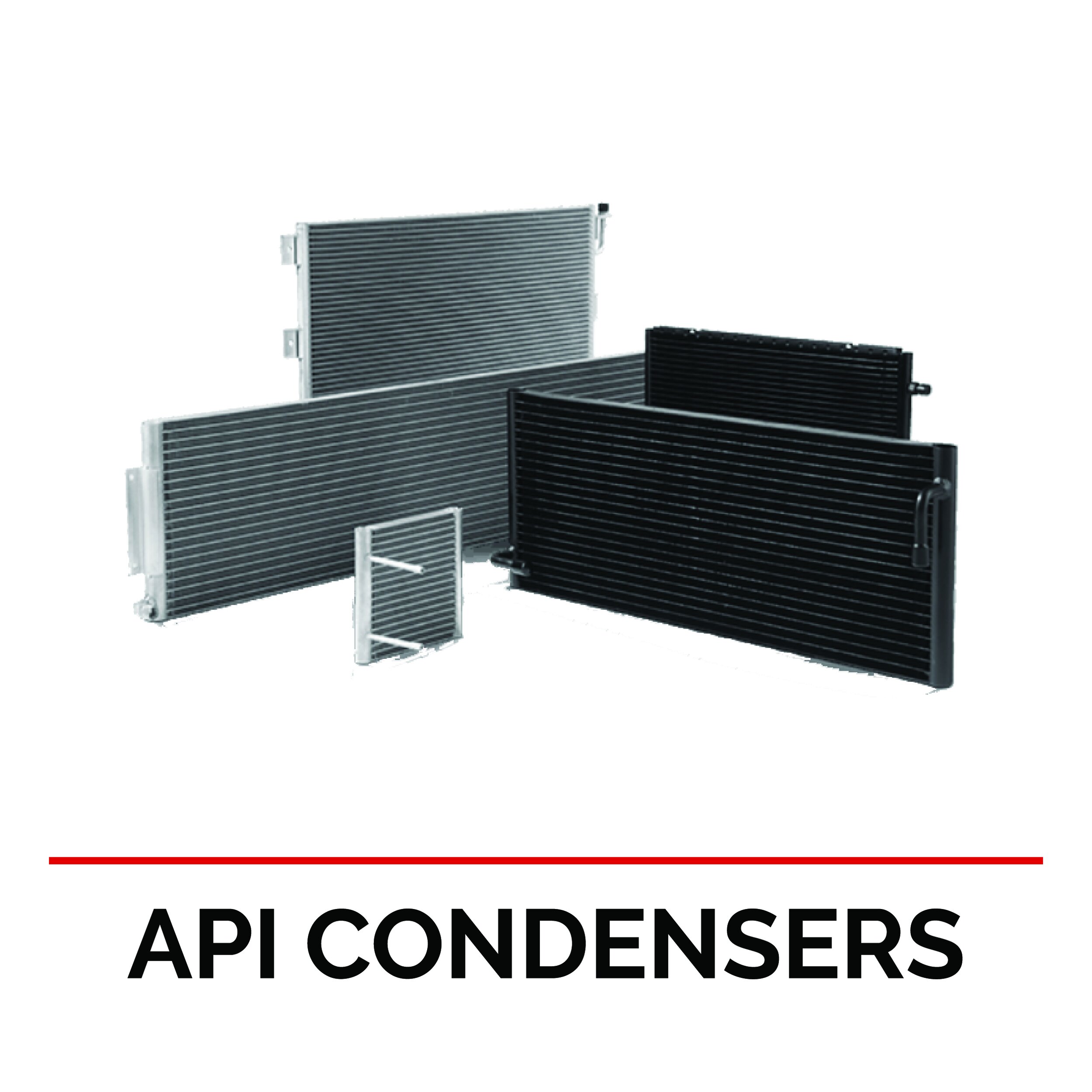

Microchannel Coil Heat Exchangers

Our Microchannel coil heat exchangers are designed for high efficiency and compact size, ideal for modern cooling and heating applications. Using flat tubes with multiple microchannels, these exchangers increase the surface area for heat transfer while minimizing volume.

Common applications include air cooled refrigeration systems and heat pumps. They offer superior heat transfer capabilities due to the increased surface area, reduced refrigerant charge leading to cost savings and environmental benefits, and a lightweight, compact design suitable for space-constrained applications.

Shell & Tube Heat Exchangers

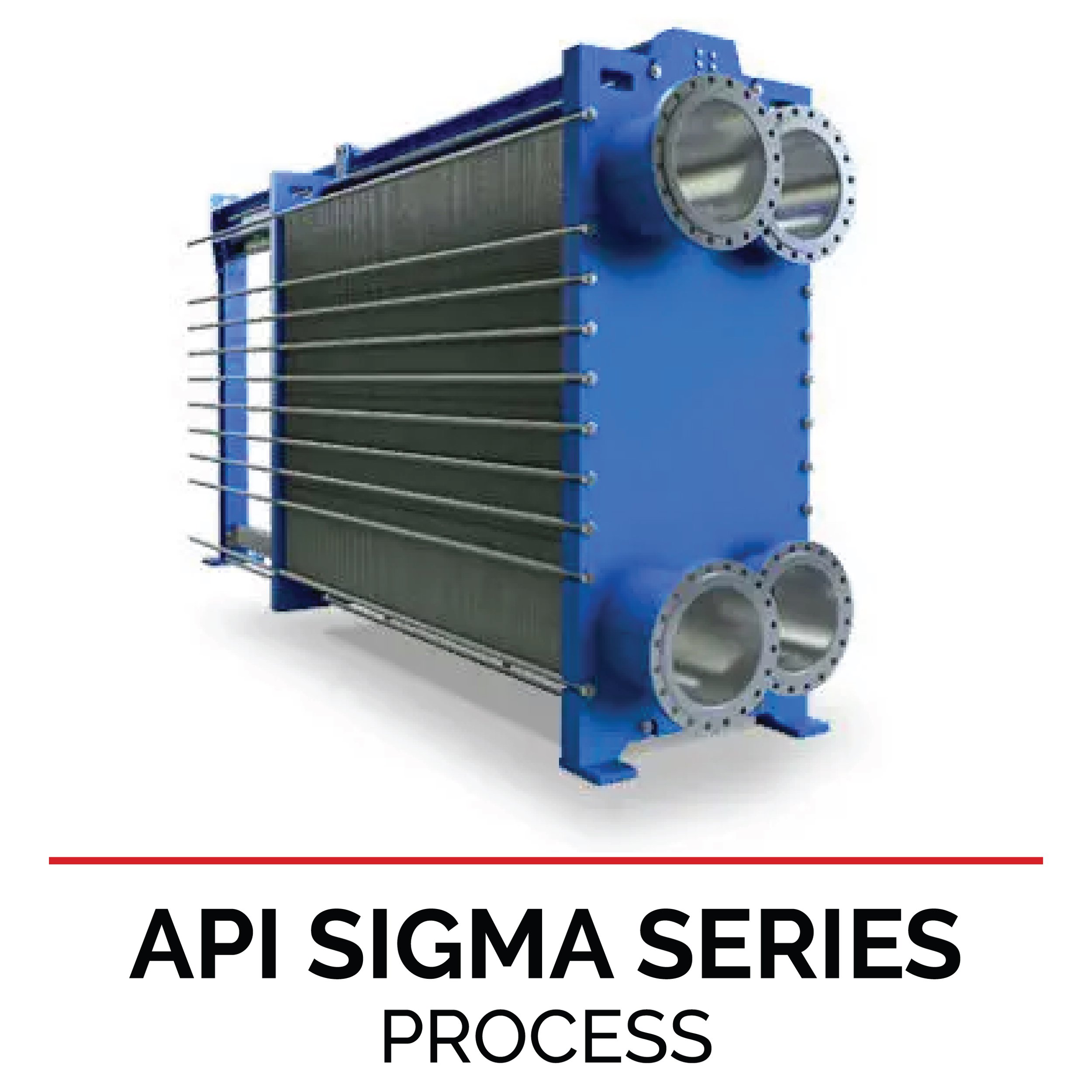

Our Shell & tube heat exchangers are a classic design, widely used for their durability and efficiency. They consist of a series of tubes housed within a larger cylindrical shell. One fluid flows through the tubes while another fluid flows around them within the shell, facilitating heat transfer. These exchangers are commonly found in oil refineries, chemical processing plants, and power stations. They are valued for their ability to handle high pressures and temperatures, as well as their capacity to manage large heat transfer areas.

Corrugated Shell & Tube Heat Exchangers

Our Corrugated shell & tube heat exchangers enhance the traditional design by incorporating corrugated tubes, which increase turbulence and heat transfer efficiency. This enhanced surface design modification results in higher thermal performance and reduced fouling compared to standard shell & tube exchangers. These are particularly effective in applications requiring efficient heat transfer and reliability under varying operating conditions. Our corrugated shell & tube heat exchangers are ideal for industries such as petrochemical, pharmaceutical, and food processing.

Fan Cooled Heat Exchangers

We also offer Fan cooled heat exchangers that utilize forced air to remove heat from a fluid. Our exchangers are equipped with fans that blow air over finned tubes, enhancing the cooling process. They are widely used in applications where water availability is limited or where air cooling is more economical. Common applications include automotive cooling systems, industrial machinery, and HVAC units.

Shell & Plate Heat Exchangers

Our Shell & plate heat exchangers combine the benefits of shell & tube and plate heat exchangers. They feature a series of plates within a shell, offering high efficiency and compact design. This hybrid approach provides the durability of shell & tube exchangers with the high thermal performance of plate heat exchangers. They are suitable for applications requiring high-pressure resistance and efficient heat transfer, such as chemical processing and energy production. Our shell & plate heat exchangers are engineered to deliver superior performance and durability.

Industries Served by our Heat Exchangers

From industrial cooling and heating solutions to sanitary equipment for food processing, our comprehensive product line caters to various industries, including chemical, pharmaceutical, energy, food and beverage, HVAC, automotive, and power generation.

For example, in the chemical industry, our heat exchangers facilitate efficient heat transfer in reactors and distillation columns. In the pharmaceutical industry, they maintain precise temperature control in production processes. In the energy sector, they optimize heat recovery systems in power plants, while in the food and beverage industry, they ensure sanitary conditions in processes like pasteurization and brewing.

Why Choose OEM Sales Inc.’s Heat Exchangers?

OEM Sales Inc. is the preferred choice due to our expertise, high-quality materials, and manufacturing standards. With years of experience and trusted partners, we offer the best solutions and exceptional customer support, from consultation to after-sales service. We provide heat exchangers for your specific requirements, ensuring outstanding performance and longevity. Contact us today to learn more about our heat exchangers and how we can support your operations.